Inquiry

Form loading...

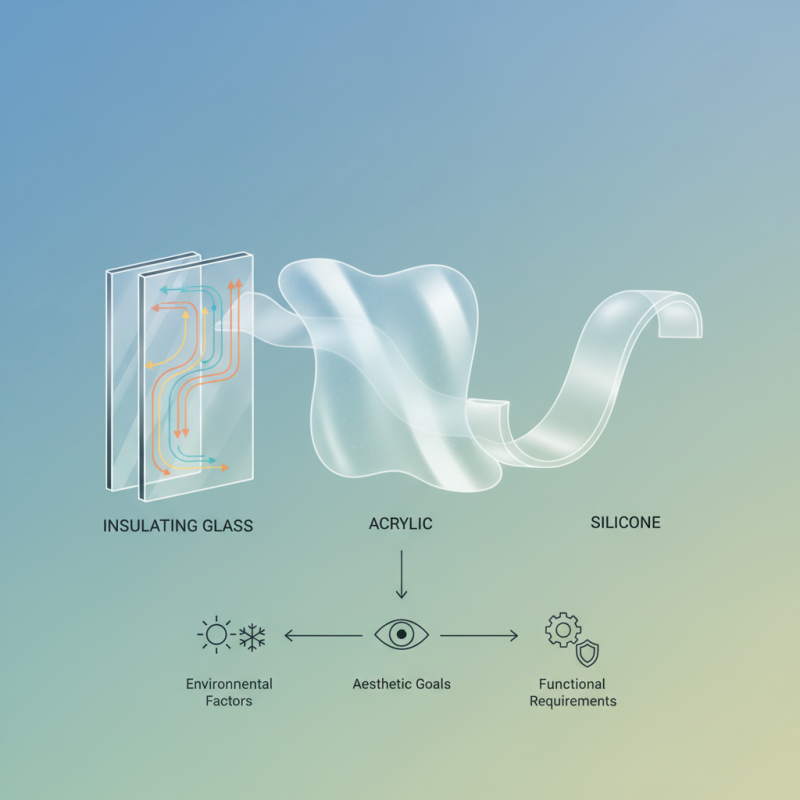

Choosing the right materials for your project can be daunting. One crucial consideration is "Insolating Glass Acrylic Silicone." This material group serves various purposes, from insulation to aesthetic appeal. Understanding each component’s unique properties is vital.

Insolating Glass offers excellent thermal resistance. It is often preferred for its clarity and durability. Acrylic, on the other hand, is lightweight and versatile. It can mimic glass at a lower cost. Silicone is essential for sealing and providing flexibility in applications.

However, selecting the right combination can be tricky. You must consider environmental factors, aesthetic goals, and functional requirements. This decision impacts energy efficiency and overall project success. Take the time to reflect on your unique needs. Balancing these factors can lead to a more effective solution.

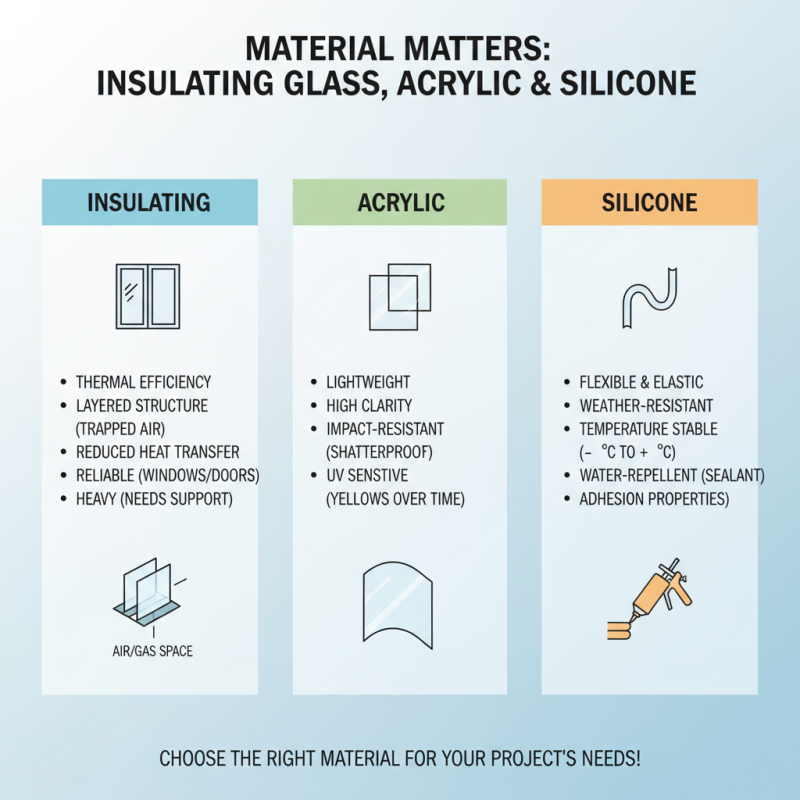

When selecting insulating glass, acrylic, and silicone, it's important to understand each material's unique properties. Insulating glass provides excellent thermal efficiency. It’s reliable, often used in windows and doors. Its layered structure traps air, reducing heat transfer. However, it can be heavy and may require additional support during installation.

Acrylic is lighter and more versatile. It offers good insulation for various applications. It’s easier to cut and handle than glass. Still, acrylic can scratch easily and may not withstand extreme temperatures as effectively. You should consider both pros and cons carefully.

Silicone is a flexible sealant, often used in conjunction with glass and acrylic. It helps seal gaps and improve insulation. However, its longevity can vary based on environmental conditions. In some cases, it may deteriorate faster than expected. Regular inspection is key, as problems can go unnoticed until they worsen. Choose these materials wisely and keep re-evaluating their performance for the best results in your projects.

When choosing insulating materials for projects, understanding their unique properties is crucial. Acrylic offers excellent clarity and high light transmission, reaching up to 92%. This makes it a popular choice for applications requiring transparency. However, it is susceptible to scratching, which can lead to maintenance challenges. In instances where longevity and durability are paramount, this property can be a drawback.

Silicone, on the other hand, is a flexible and resilient material. It can withstand extreme temperatures, ranging from -100°F to 500°F. This makes silicone ideal for sealing applications where thermal expansion is a concern. However, its adhesion properties can vary. Not every surface adheres well to silicone, posing potential issues in certain projects. The industry reports show that while silicone is versatile, careful consideration of surface compatibility is essential for optimal performance.

Insulating glass provides superior thermal efficiency. It can reduce energy loss by up to 50% compared to single-pane windows. This efficiency, however, comes with weight considerations. Heavy panels can complicate installation, making it essential to evaluate structural capabilities. Engineers emphasize the need for thorough planning when integrating these materials into projects. Balancing properties and applications requires a nuanced understanding of how each material behaves under specific conditions.

| Material | Thermal Insulation | Durability | Weight | Cost |

|---|---|---|---|---|

| Insulating Glass | High | Very High | Heavy | High |

| Acrylic | Moderate | Moderate | Lightweight | Moderate |

| Silicone | Low | High | Very Light | Low |

Choosing the right insulative materials for your project is crucial. Evaluating project requirements helps ensure optimal selections. Different projects demand varying insulation properties. For instance, energy efficiency is essential in residential buildings, where up to 40% of energy is lost through windows.

When assessing needs, consider factors like thermal performance and moisture resistance. Research indicates that acrylic materials offer a higher R-value compared to glass. This means they can provide better insulation. However, acrylic may scratch more easily. Therefore, the choice isn't always clear-cut.

Cost is another significant factor. A study shows that silicone products can reduce installation time and labor costs by up to 20%. Yet, their upfront cost might be higher. Balancing these aspects—performance, durability, and cost—requires careful thought. Often, feedback from previous projects can provide deeper insights. Conducting thorough evaluations may reveal gaps in understanding material properties. This iterative process is essential in decision-making.

This chart evaluates the performance ratings of insulating materials based on key factors such as thermal resistance, transparency, weight, cost, and durability.

When selecting insulating materials, comparing costs and performance is vital. Glass, Acrylic, and Silicone each have unique attributes.

Glass is known for its excellent thermal insulation. According to industry reports, double-glazed glass can reduce heat loss by up to 50%. However, it often comes with a higher price tag.

Acrylic offers a lightweight alternative with decent insulating properties. It can also be more cost-effective, with a price point that is usually 40% lower than glass. Its performance, however, may not match that of superior glass options. Some reports indicate that acrylic loses heat more quickly than glass.

Silicone, while not typically used for insulation alone, serves as an excellent sealant. It's flexible and can fill gaps that compromise insulation. However, relying solely on silicone may result in loss of performance over time. This reflects the need for a balanced approach, combining multiple materials for optimal results. Each choice has trade-offs that require careful consideration in your projects.

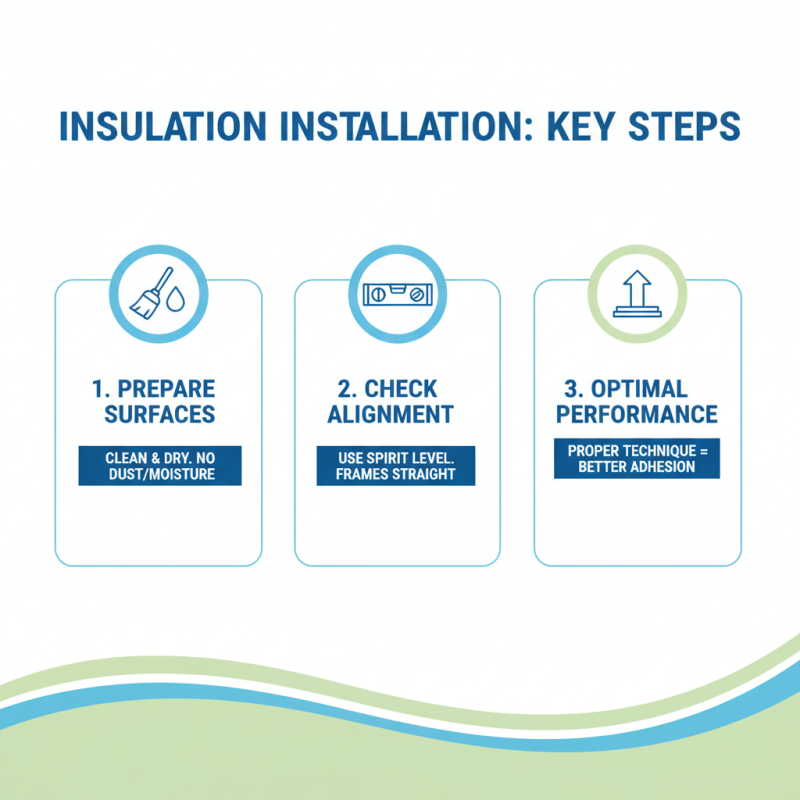

When installing insulating materials, proper techniques are crucial for optimal performance. Start by ensuring the surfaces are clean and dry. Dust and moisture can compromise adhesion. Use a spirit level to ensure your frames are straight. This will prevent misalignment during installation.

Tips: Measure twice, cut once. It saves time and reduces waste. Keep tools handy and organized. This can make the process smoother.

Regular maintenance is essential for longevity. Inspect seals for wear. If they appear cracked or loose, consider reapplying silicone. Check for condensation between layers of glass. This could indicate a failure in insulation, requiring immediate attention.

Tips: Clean surfaces with mild soap and water. Avoid harsh chemicals that can damage materials. Always refer to manufacturer guidelines for specific maintenance instructions. Small, consistent care can make a big difference.