Inquiry

Form loading...

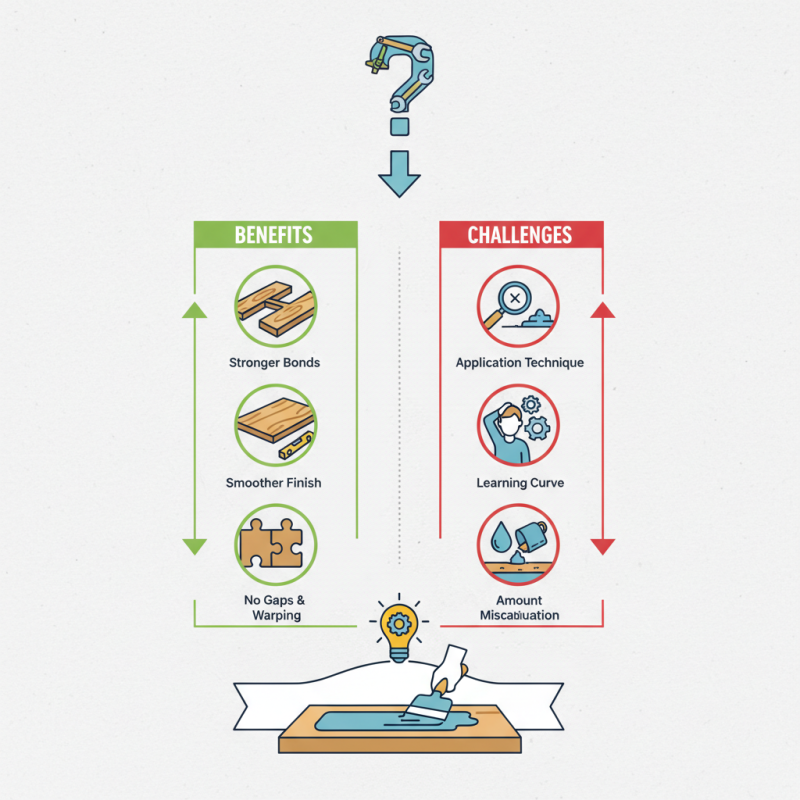

In the realm of construction and crafting, the choice of adhesive can significantly impact project longevity. Low Shrinkage Liquid Nails have emerged as a significant solution, specifically designed to minimize shrinkage during the drying process. Industry expert Dr. Emily Carter, a leading adhesive scientist, states, "Low Shrinkage Liquid Nails not only provide strong bonds, but they also ensure a smoother finish."

This innovative product addresses concerns such as warping and gaps, often seen with traditional adhesives. Users have observed that the application of Low Shrinkage Liquid Nails results in cleaner, neater projects. However, some admit there are learning curves in achieving optimal results consistently. The application technique, for instance, can greatly influence performance. A few users noted that even small miscalculations in the amount applied led to visible imperfections.

As we explore the top Low Shrinkage Liquid Nails available for 2026, it’s essential to recognize not just the benefits, but also the potential pitfalls. Paying attention to details during application can enhance the bonding process and overall outcome. Embracing this knowledge will help elevate your projects to new heights.

Low shrinkage liquid nails are crucial for various construction and crafting projects. These adhesives reduce the risk of gaps and misalignment as they cure. Traditional adhesives often shrink, leading to weakened bonds. A strong bond is essential in applications like woodworking, tiling, and home repairs.

When using low shrinkage liquid nails, it’s important to consider surface preparation. Clean surfaces allow the adhesive to perform better. However, some users overlook this step, resulting in adhesion failure. Additionally, applying too much adhesive can lead to oozing, which complicates cleanup.

The importance of low shrinkage liquid nails cannot be overstated. They provide peace of mind in structural applications. Yet, some may still face issues with curing time. Patience is key, and rushing can lead to subpar results. Understanding these nuances helps achieve optimal performance in your projects.

When selecting low shrinkage liquid nails, focus on key features that ensure a strong bond. One critical feature is the adhesive's viscosity. A thicker consistency can provide better control during application. This helps prevent dripping and ensures the adhesive stays where you need it. Additionally, an easy application process is vital. Look for products that allow for smooth dispensing from the tube. No one enjoys wrestling with a difficult nozzle.

Another aspect to consider is the curing time. A rapid curing adhesive can save time on projects. However, if it cures too quickly, it may not allow for adjustments. This balance is tricky. You'll want to be cautious about how fast it sets. Moisture resistance is also essential. In some cases, projects will be exposed to humidity or water. A good low shrinkage liquid nail should withstand such conditions without compromising its bond.

Lastly, consider the temperature range for application. Some adhesives work well only in specific temperatures. If you're working in fluctuating conditions, this can be an issue. Remember, even the best product may not perform as expected due to environmental factors. Always evaluate what will work best for your unique project conditions. Taking time to choose the right adhesive can greatly impact your project’s outcome.

Low shrinkage liquid nails are becoming essential for various construction and DIY projects. Their ability to minimize shrinkage is vital for maintaining structural integrity. According to industry reports, shrinkage can lead to gaps and weakened bonds in materials, which may compromise the overall quality. A study indicates that using low shrinkage adhesives can reduce these issues by up to 30%.

When selecting a liquid nail, consider application ease and drying time. Many products on the market offer quick setting without sacrificing strength. However, it is essential to remember that not all low shrinkage formulas perform equally well in different environments. Temperature fluctuations and humidity can affect bonding efficacy.

While most manufacturers claim high performance, real-world tests often reveal discrepancies. Some consumers report that certain products do not meet their expectations. It's important to conduct personal trials before committing to a large project. Understanding this can lead to better choices and satisfaction in the end.

| Product Name | Shrinkage Rate (%) | Drying Time (minutes) | Bonding Strength (psi) | Suitable Materials |

|---|---|---|---|---|

| Low Shrink Adhesive A | 0.5 | 20 | 3000 | Wood, Metal, Ceramics |

| Sealant X | 0.6 | 15 | 2800 | Plastic, Wood |

| Ultra Bond | 0.4 | 10 | 3200 | Wood, Metal, Concrete |

| Flexi Grip | 0.7 | 25 | 2500 | Glass, Metal |

| Quick Set Adhesive | 0.3 | 5 | 3400 | Wood, Concrete |

Low shrinkage liquid nails are essential in many construction and DIY projects. Their unique formula minimizes shrinkage, ensuring strong bonds. This characteristic is especially beneficial for woodwork and paneling, where precision is key. According to industry reports, nearly 70% of builders prefer low shrinkage options for long-lasting results.

Using low shrinkage liquid nails can enhance the quality of various applications. They work well for mounting trim, securing flooring, or bonding materials in furniture manufacturing. This adhesive's reduced shrinkage helps maintain alignment, which is crucial for both aesthetics and functionality. The accuracy it provides translates into cleaner lines and fewer callbacks for repairs.

Tip: Always prepare surfaces properly before application. Clean them from dust and debris. A rough surface aids adhesion. Consider testing a small area first. This way, you can assess cure times and bond strength. Remember, humidity and temperature can affect drying times. Keeping conditions optimal can improve your results significantly.

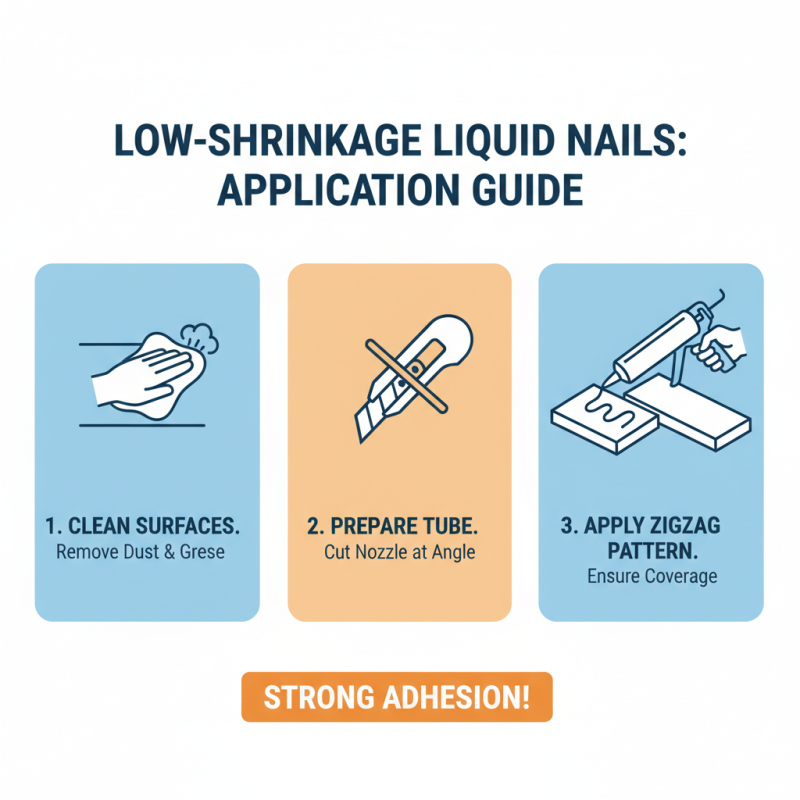

When using low shrinkage liquid nails, proper application is essential. Start by cleaning the surfaces. Dust and grease can disrupt adhesion. A simple wipe with a cloth can make a big difference. Prepare the tube carefully. Cut the nozzle tip at an angle for better control. Applying the adhesive in a zigzag pattern can help ensure coverage.

When joining materials, press them firmly together. Hold for a few seconds to allow initial bonding. Be aware of drying times. Rushing may lead to weak connections. Sometimes, you might find misalignment in your project. It’s okay; just reposition and try again.

Always check the temperature and humidity levels before starting. Elevated moisture can affect drying. If conditions aren’t ideal, consider waiting for a better day. Even the best plans can go awry. Learning from each misstep will improve your technique. Remember to read the instructions closely for the best results.