Which joints need to be sealed when setting up a sink

Sealing seams is a critical step in sink installation to ensure the longevity and functionality of your sink. Properly sealed seams prevent water from penetrating, which can cause structural damage, mold, and mildew. Knowing which seams need to be sealed can save you trouble, time, and money later.

When sealing your sink, focus primarily on seams at sink attachments, where plumbing fixtures meet, and where the sink meets the edge of the countertop. Because of their frequent contact with water, these seams are particularly susceptible to leaks and damage if not properly sealed.

When sealing your sink, focus primarily on seams at sink attachments, where plumbing fixtures meet, and where the sink meets the edge of the countertop. Because of their frequent contact with water, these seams are particularly susceptible to leaks and damage if not properly sealed.

The following are the joints that need to be sealed and the operation suggestions:

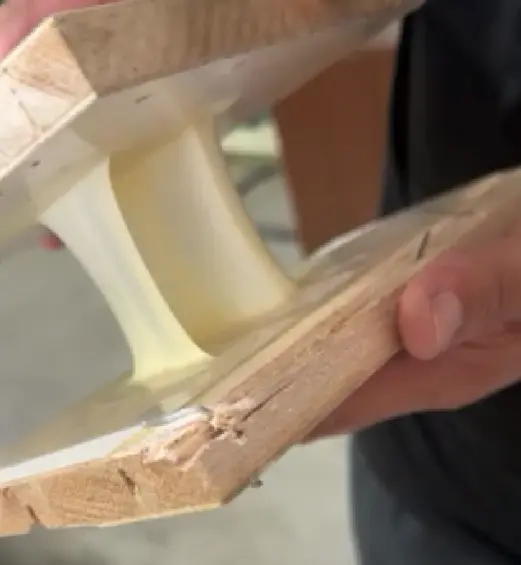

1. Joint between sink and countertop

Location:

Around the edge of the sink and the countertop.

Importance:

Prevent water from seeping under the countertop to prevent the cabinet from getting damp or moldy.

Operation:

Evenly apply anti-mold Silicone Sealant.

When installing the under-counter basin, pre-apply sealant before fixing the mounting bracket to ensure a complete fit.

2. Faucet and accessories installation

2. Faucet and accessories installation

Location:

The contact surface between the faucet base and the countertop or sink. And the perforation of accessories such as soap dispensers and water purifier faucets.

Importance:

Prevent water from seeping under the countertop from the installation hole.

Operation:

Apply silicone to the edge of the hole before installation, or install a rubber gasket at the bottom of the accessory.

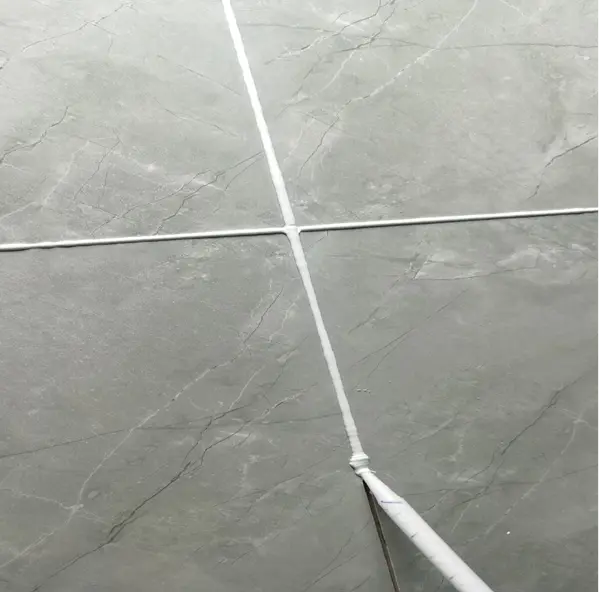

3. Seam between backsplash and countertop/sink

Location:

Where the back of the sink meets the splashback.

Importance:

Avoid water from seeping into the gap along the wall.

Operation:

Fill the seam with anti-mold silicone and scrape the surface.

Notes

a.Clean the surface: Make sure the joints are dry, free of oil or debris before sealing.

b.Apply evenly: The silicone needs to be applied continuously and evenly to avoid breakpoints. It can be smoothed with a scraper or wet fingers.

c.Curing time: Wait 24-48 hours before using the sink to ensure that the sealant is fully cured.

d.Regular inspection: Check the sealant status every six months and repair cracks or mold in time.